MACHINE

REMANUFACTURE

Sheet metal machines rebuilt to original specifications – AS NEW

Outstanding service, technical knowledge, and attention to detail go into the remanufacture of every machine that enters our facility. We rebuild to match the exact specifications of the original machine using a combination of reused, repaired and new parts. Worn out or obsolete components are replaced or repaired and parts subject to degradation or which affect performance or expected life are replaced. This thorough and precise process eliminates any defects in the original design and minimises ongoing maintenance costs.

The result is a remanufactured machine with the same specification, function, quality and performance as a brand new machine – a turnkey solution. We stock a large selection of machines across the whole Amada range and our engineers are happy to advise which machine best suits your intended application.

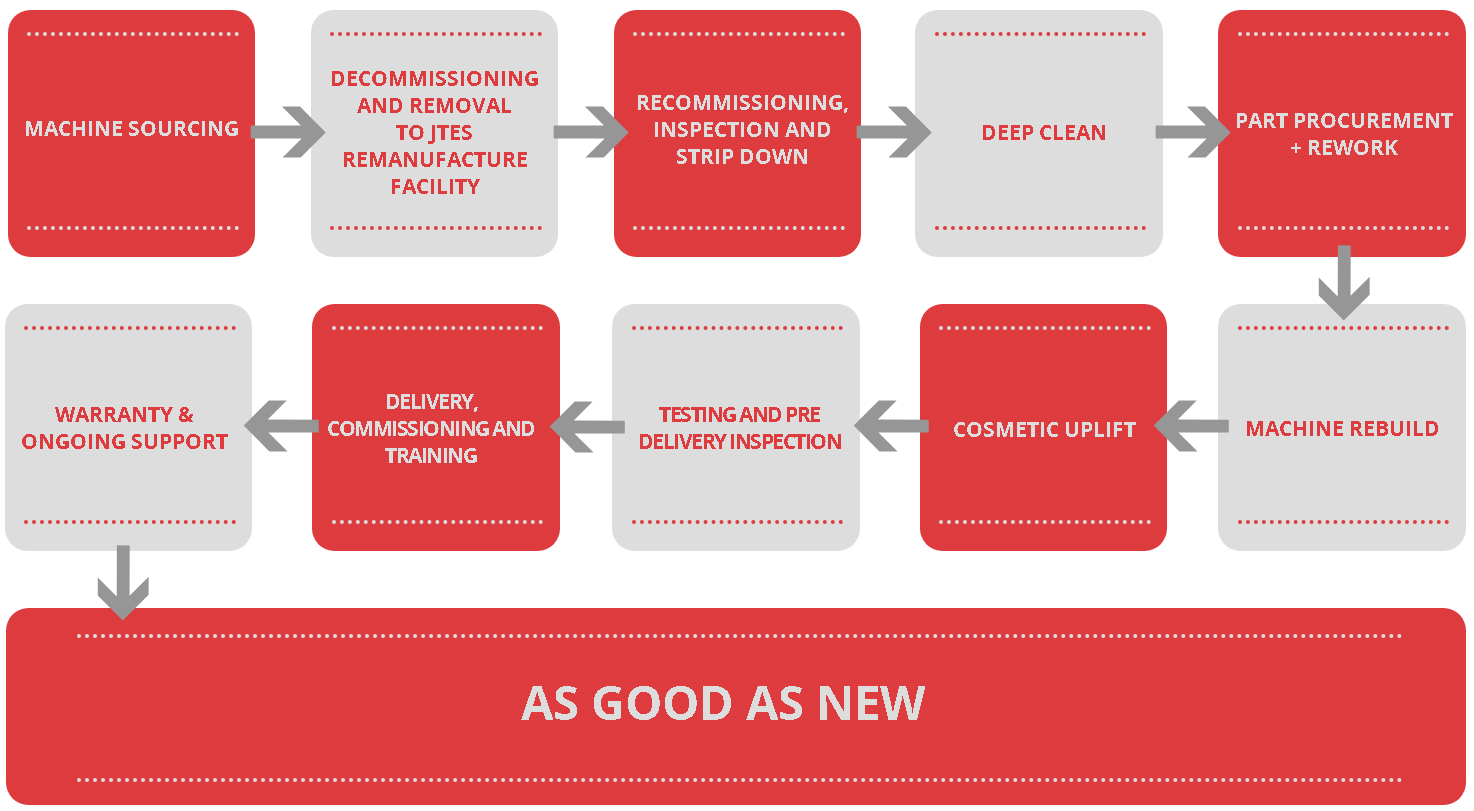

The Remanufacturing Process

Remanufacture Process in Detail

Machine Sourcing

Decommissioning and Removal to JTES Remanufacture Facility

Recommissioning, Inspection and Strip Down

Deep Clean

Part Procurement and Rework

Machine Rebuild

Cosmetic Uplift

Testing and Pre-delivery Inspection

Delivery, Commissioning and Training

Warranty and Ongoing Support

See the Remanufacturing Process in Action

We are proud of our work and invite you to visit our workshop at every stage of the remanufacturing of your machine. We especially encourage customers to witness the testing process, which demonstrates our high standards and drive for continuous improvement. Contact us to arrange your visit.